PDLC Film Lifespan: How Long Does Smart Film Actually Last?

When considering the integration of switchable technology into a residential or commercial project, PDLC film lifespan is often the first question that arises: Is this a short-term novelty or a long-term architectural investment?

At Smart Pro Glass, we believe in radical transparency—pun intended. While the visual appeal of Polymer Dispersed Liquid Crystal (PDLC) technology is immediate, its longevity relies on science, chemistry, and proper handling.

Understanding the lifespan of PDLC film requires moving beyond simple timeframes and looking at how the technology interacts with electricity, installation materials, and its environment.

Table of Contents

The Short Answer

What is the expected lifespan of PDLC film?

High-quality PDLC smart film is engineered to perform reliably for over 10 years under normal usage, provided it is installed professionally and maintained correctly.

Rather than measuring life solely in years, engineers often measure it in switching cycles. Premium smart film is tested to withstand millions of switches from opaque to transparent without significant degradation in clarity or response speed. However, achieving this decade-plus longevity requires adherence to specific operating protocols, particularly regarding “OFF” times.

Technical Note: In its natural, unpowered state, PDLC film is opaque (providing privacy). It becomes transparent only when an electrical current aligns the liquid crystals.

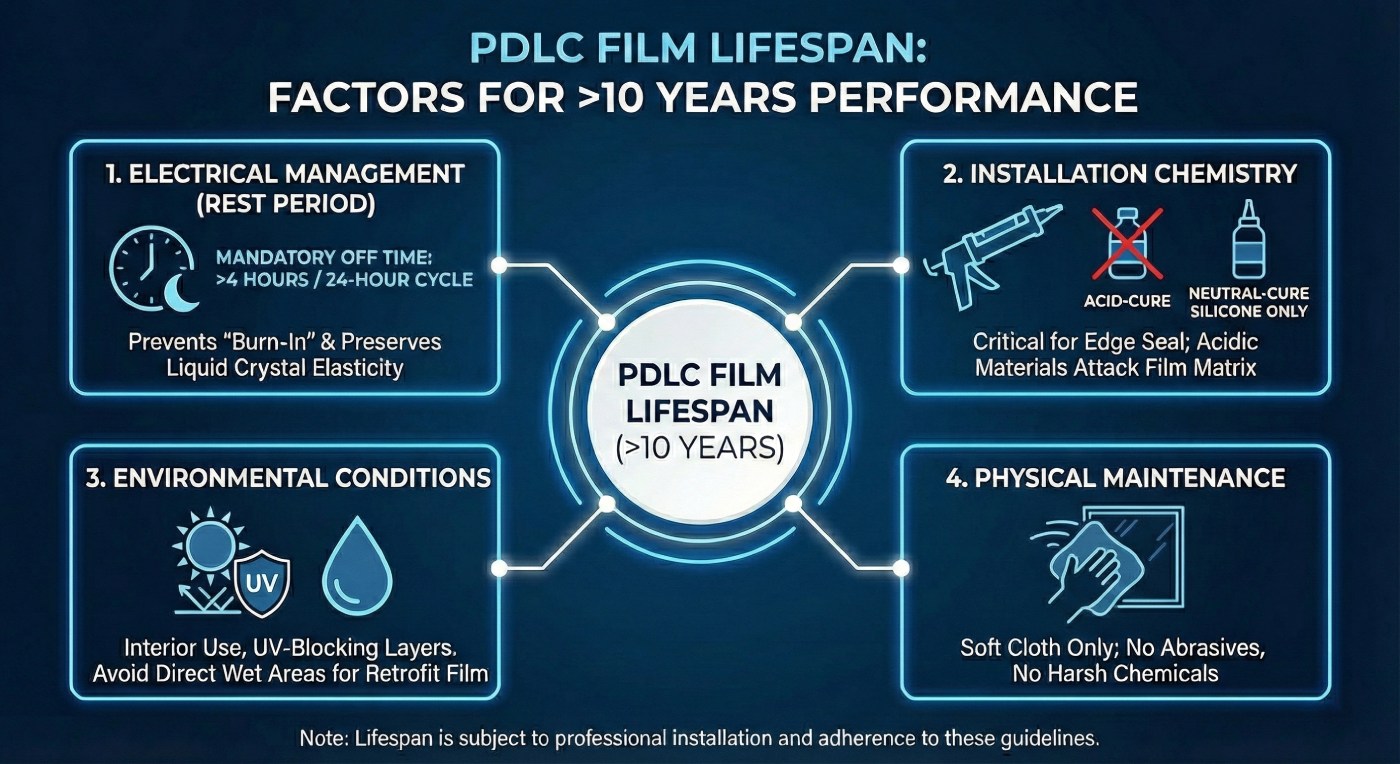

The 4 Factors That Determine Longevity

The durability of smart film is not a fixed number; it is a variable result of four specific factors. Understanding these will ensure your installation retains its premium finish for the long haul.

1. Electrical Management (The “Rest” Period)

The single most critical factor in PDLC film lifespan is how you manage the power.

Because the film requires current to remain transparent, there is a temptation in commercial settings (like boardrooms or retail displays) to leave the glass “ON” continuously. This is detrimental to the film.

If liquid crystals are held in alignment by an electrical current 24/7, they can lose their elasticity or ability to scatter light effectively when the power is cut. This can result in “burn-in” or a hazy appearance in the transparent state.

The Golden Rule: To preserve the lifespan of the liquid crystals, PDLC film requires a mandatory “OFF” period of at least 4 hours within every 24-hour cycle. Simply turning the film off overnight or during non-business hours is usually sufficient to maintain optimal performance for over a decade.

2. Installation Chemistry

The chemistry of the installation materials is just as important as the film itself.

Self-adhesive smart film is applied to existing glazing, often requiring silicone sealing at the edges to prevent moisture ingress and secure the wiring. This is a high-risk stage if performed by non-specialists.

- The Danger: Standard acid-cure silicones release acetic acid as they cure. This acid attacks the delicate matrix of the PDLC film, causing yellowing, delamination, or complete failure at the edges.

- The Solution: We strictly mandate the use of neutral-cure silicone only. This ensures a chemical-free bond that protects the film’s edge without compromising the liquid crystal layer.

3. Environmental Conditions

While PDLC film is robust, it is an electrical component. Its lifespan is heavily influenced by where it lives.

- Interior vs. Exterior: Smart film is designed primarily for internal applications or the internal face of external windows.

- UV Exposure: High-quality films, like those supplied by Smart Pro Glass, include UV-blocking layers (rejecting over 98% of harmful UV rays). This protects interiors from fading but also protects the liquid crystals themselves from yellowing over time.

- Moisture: In wet areas (bathrooms or wet rooms), standard retrofit film is risky unless the edges are hermetically sealed. For these environments, we typically recommend Laminated Smart Glass rather than retrofit film to ensure longevity.

4. Physical Maintenance

Smart film is durable, but it is not scratch-proof. The “hard coat” on the outer layer prevents minor scuffs, but abrasive cleaning is the enemy of longevity.

Using harsh chemicals (ammonia or bleach) or abrasive scrubbing pads will degrade the surface over time, leading to a permanent haze that cleaning cannot remove. A simple wipe with a soft microfibre cloth is all that is required.

Smart Film vs. Laminated Smart Glass: A Durability Comparison

While the core technology (PDLC) is identical, the housing method affects the lifespan.

| Feature | Retrofit Smart Film | Laminated Smart Glass |

| Construction | An adhesive layer is applied to the existing glass surface. | PDLC layer sandwiched between two sheets of glass using EVA/PVB interlayers. |

| Vulnerability | Exposed to surface scratches and direct impact. | Completely protected inside the glass unit. |

| Moisture Resistance | Requires careful edge sealing. | High resistance; ideal for wet rooms/showers. |

| Lifespan Impact | 10+ years (subject to surface care). | 10+ years (limited only by the glass unit integrity). |

For high-traffic areas where physical impact is likely, Laminated Smart Glass offers a structurally superior lifespan simply because the PDLC layer is inaccessible to human hands.

Technical Specifications & Performance

To understand if your film is ageing correctly, you must know how it should perform when new. Degradation is rarely sudden; it is usually a slow shift in these optical metrics.

- Visible Light Transmittance (VLT): In the ON state, premium film should achieve >88% transmittance. If this drops significantly, the crystals may be failing to align.

- Haze: In the transparent state, there is always a minimal amount of natural haze due to the physics of liquid crystals. High-quality manufacturing keeps this below 3%.

- Viewing Angle: A sign of a healthy lifespan is a consistent view from roughly 150°. If the film appears clear head-on but opaque from an angle, it may indicate crystal degradation.

Common Misconceptions About PDLC Durability

Myth: “Smart film consumes high energy, which burns it out.”

Fact: Smart film is incredibly energy-efficient, typically consuming less than 5 watts per square metre. It is not the amount of energy that affects lifespan, but the duration of continuous voltage without a rest period.

Myth: “Smart film provides 100% blackout.”

Fact: PDLC provides privacy, not blackout. In the OFF state, it diffuses light (opaque), preventing visibility, but it still allows light to filter through. This behaviour does not change over the film’s lifespan.

Summary: Key Takeaways for Long Life

If you are planning a project with Smart Pro Glass, adhering to these four pillars will ensure your investment lasts over a decade:

- Power: Ensure the system is turned OFF for at least 4 hours every 24 hours.

- Sealant: Use only non-acidic, neutral-cure silicone during installation.

- Cleaning: Use soft microfibre cloths and avoid excess liquid at the edges.

- Wiring: Ensure busbars are not shorted by metal frames during installation.

Frequently Asked Questions

Does PDLC Film Yellow Over Time?

High-quality PDLC films are manufactured with UV inhibitors to prevent yellowing. However, using cheap, non-neutral silicone sealants or exposing the film to extreme, prolonged heat without ventilation can accelerate discolouration.

Can I Leave My Smart Glass Clear (ON) 24/7?

No. We strongly advise against this. To maintain the “over 10 years” lifespan expectancy, the crystals need to relax into their natural opaque state for at least 4 hours per day. A timer switch is a simple way to automate this.

Is the Warranty Void if I Install it Myself?

Yes. PDLC film is a sensitive material. Improper handling (creasing the film, using acidic silicone, or incorrect wiring) acts as the primary cause of early failure. For commercial projects, we always recommend professional installation to ensure warranty validity.

What Happens When PDLC Film Reaches the End of Its Life?

It does not always simply “stop working” overnight. End-of-life usually manifests as the film becoming less transparent in the ON state (increased haze) or spots appearing where crystals no longer respond to voltage.

For technical data sheets, wiring diagrams, or to discuss the suitability of smart film for your specific project, please visit our Downloads Section or contact the Smart Pro Glass technical team.