Technology

What is Smart Glass Technology

Smart Glasses are a type of controllable glass whose light transmission properties under light, thermal, and electrical vary. Smart Glass has two broad categories: passive and active. The passive subcategory includes thermochromic and photochromic. The active subcategory, includes electrochromic (EC), suspended particle devices (SPD), and polymer-dispersed liquid crystal (PDLC).

PDLC

What is PDLC

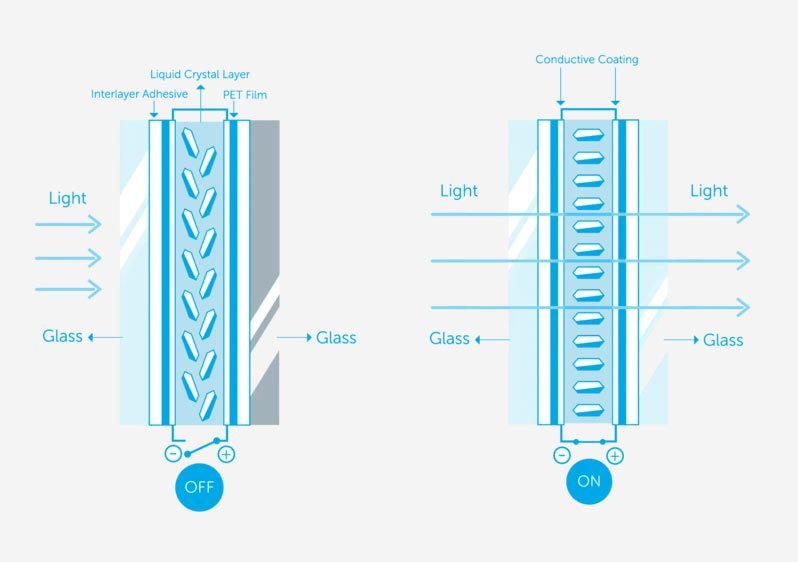

PDLC is an active smart glass technology meaning it needs electricity to turn on and off. Polymer Dispersed Liquid Crystal (PDLC) Film consists of micron-sized droplets of liquid crystal dispersed in an optically isotropic polymer matrix. By choosing appropriate combinations of liquid crystal and polymer material, the PDLC film can be electrically switched from a light-scattering or opaque “off state” to a non-scattering or transparent “on state”. In the “off state”, the PDLC film appears milky white due to the refractive index mismatch encountered by incoming light at the liquid crystal/polymer interface.

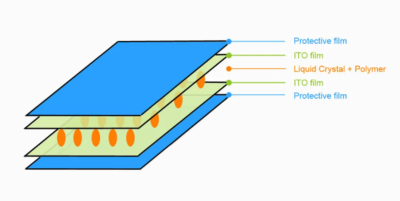

Indium Tin Oxide (ITO) technology is a mixture of indium oxide and tin oxide. Being semi-conductive, it has a high electrical conductivity. Moreover, thin layers of about 200 nm are transparent in the area of visible light while infrared light is reflected. Indium tin oxide has a density of approximately 7 g/cm³ and is a white to yellowish color. Indium tin oxide is an important transparent, electrically conductive material.

At the flick of a switch, SmartPro Ultra Clear Smart film becomes transparent from a dormant, milky-white translucent state. When electricity is applied, the liquid crystal molecules line up, the incident light passes through, and the smart film becomes transparent. On the other hand, when the power is off, the liquid crystal molecules are randomly oriented so that light is scattered, resulting in an opaque smart film.

Structure

PDLC Structure

Switchable PDLC type can realize the instantaneous switching of glass from transparent and opaque, less than 1s, while this number for other electrochromic smart glasses, takes about 1-3 minutes, which is unacceptable for efficient work.

Different types of Smart Film

Passive smart glass technologies are those that use natural, nonelectrical stimuli, such as heat and light, to transition from dark to light and vice-versa.

On the other hand, thermochromic glass uses heat from direct sunlight to tint the glass. As the amount of sunlight increases, this type of smart glass becomes darker. In the photochromic glass, the level of transparency is changed in response to the light intensity.

Active smart glass technologies are those that respond to an electrical stimulus, which gives control to the user, by providing on-demand results.

- Electrochromic (EC) glass is a type of active smart glass whose color change by applying external DC voltage or current, turning the glass from clear to dark. Typical use includes solar control for exterior glass. Electrochromic glasses are not suitable to bring privacy as in their darkest state, the visible light transmission can be less than three percent, as it can still be seen through.

- Suspended particle devices (SPD) are small light-absorbing microscopic particles, that respond to an external AC power source in a matter of seconds transitioning from clear to dark. When voltage is applied, the suspended particles align, which allows light to pass. This technology is generally used for light-control applications – most commonly auto glass, skylights, sunroofs, portholes, aircraft windows, and marine windows. It provides weak to moderate privacy.

- Polymer-dispersed liquid crystal (PDLC) is an innovative technology that switches from opaque to clear in milliseconds using AC current, regardless of the size of the glass. It has light-scattering power when an electric field is applied and can be used for a range of exterior and interior applications. Products using this technology are available in a self-adhesive switchable film that can retrofit to existing surfaces as well as a laminated switchable glass. In its opaque state, it gives the user complete privacy, since you can’t see through it.